FUJIFILM Business Innovation has established a Circular Manufacturing Center with the objective of promoting resource circulation in Europe. The Center will be located at FUJIFILM Manufacturing Europe B.V. in the Netherlands and will commence operations with the collection and remanufacturing of toner cartridges from June 2024.

In 1995, FUJIFILM Business Innovation established a comprehensive recycling policy, which it has adhered to ever since. This policy is based on the principle of ‘zero waste’ and is designed to promote resource circulation. It encompasses the collection, reuse, and recycling of all consumed equipment and products from customers. The company’s comprehensive circular production system encompasses the entire product lifecycle, from planning and development to manufacturing and disposal. The objective is to minimise the use of new resources and maximise resource circulation through the reuse of parts from collected products.

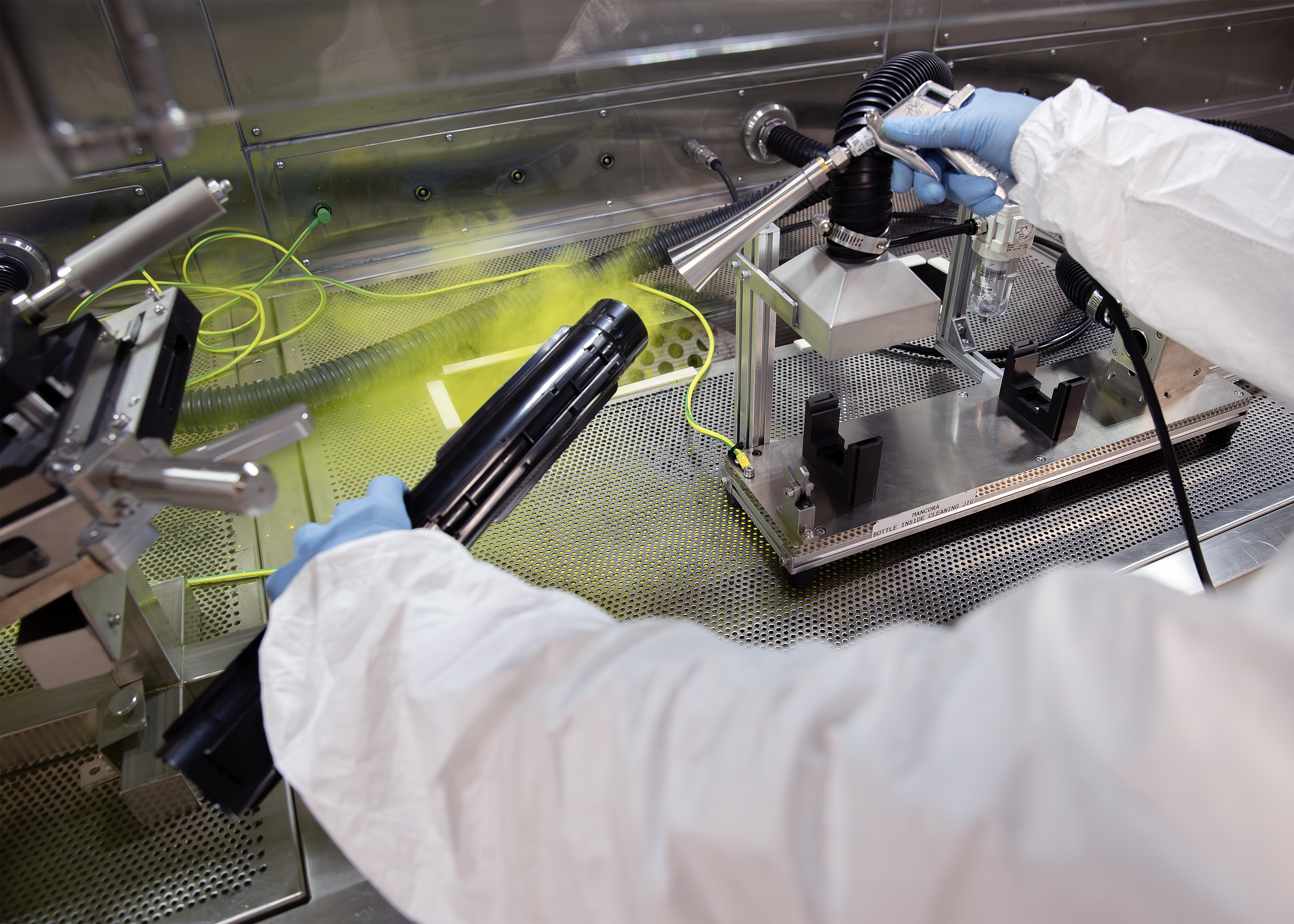

At the new Circular Manufacturing Center, FUJIFILM Manufacturing Europe B.V. will collect used toner cartridges from printers sold throughout Europe. Following disassembly, cleaning, inspection, and remanufacturing, these cartridges will be reintroduced into the European marketplace as new toner cartridges. The company has expressed its intention to extend these remanufacturing processes in the future to other products, such as multifunction printers and production printer spare parts, in addition to toner cartridges.

A notable aspect of the Circular Manufacturing Center is its dedication to sustainability. FUJIFILM Manufacturing Europe B.V. supplies all of its electricity needs from on-site wind power generation and from a purchased wind power generation company. Therefore, the newly established Circular Manufacturing Center can also achieve virtually zero CO2 emissions from the electricity it uses. Strategically located in the Netherlands, the heart of Europe, the facility benefits from an extensive manufacturing history and advantageous geographical position to enhance transportation efficiency and effectively promote resource recycling.

From its inception, FUJIFILM Business Innovation has been dedicated to environmental conservation and reducing the environmental impact of its corporate activities. The inauguration of the Circular Manufacturing Center in Europe constitutes a significant milestone in the company’s ongoing endeavours to enhance resource circulation and contribute to the circular economy.

It is important to note that the remanufactured products are derived from used items collected from customers and undergo a thorough process of disassembly, cleaning, inspection and refurbishment in order that they meet the requisite quality standards.